Even though being the most frequently used additives in water-containing creams, it has already become an open secret, that emulsifiers are not suitable for every type of skin. In extreme cases they even can cause considerable disorders of the skin barrier and favour dry skin, which in its turn not only easily loses moistness but also enables an increased penetration of harmful substances from the outside. Thus, the medicinal drug may be optimally selected in these cases, whereas the basis could be counterproductive.

Derma membrane structure

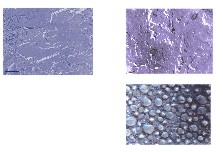

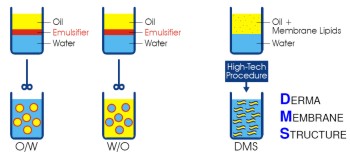

A long time has been spent on researching for bases which are more compatible to the physiological properties of the skin than the O/W or W/O emulsions which have been known so far. Based on the experiences of the liposome and nanoparticles technologies, where the structures are formed by the natural membrane component phosphatidylcholine (PC), the DMS creams have been developed. Figure:

Elektron micrograph of a DMS-cream (left above) and comparison with an O/W-emulsion (right below) and the skin barrier (right above)

DMS is an abbreviation of the term derma membrane structure. The special feature of DMS consists in the fact that its structure is very similar to the horny layers of the skin barrier and with regard to its chemical structure, it is related to the natural components of the skin. This concept consequently avoids additives like emulsifiers, perfumes, mineral oils, silicones and emulsifiers which are used in conventional products.

The membrane family

The DMS is part of the membrane family. In contrast to liposomes and nanoparticles which consist of native PC (its fatty acid population mainly is linoleic acid), the DMS contains a hydrogenated PC (with a fatty acid population of stearic acid and palmitic acid) which shows ceramide-like properties. Hence, hydrogenated PC has a high natural affinity to the lipid bilayers of the skin barrier, stabilizes the trans-epidermal water loss in a physiologically useful balance and protects the skin against the penetration of foreign substances. As it does not impede the natural skin regeneration, but on the contrary simultaneously rather supports it, it is meanwhile being used in the field of occupational skin protection1). The major components of DMS-base creams are: water hydrogenated phosphatidylcholine (extracted from soybean lecithin) oil-based substances phytosterols (e.g. extracted from shea butter) moisturizing agents (glycerine etc.)

Manufacturing and individual adaptation

Just like liposomes and nanoparticles, DMS bases cannot be produced by using conventional emulsifying technologies. The manufacturing process requires a specific high-pressure homogenization procedure and in many cases this process has to be run repeatedly.

When the DMS structure finally is built up, it acts like the skin barrier layers: it has the capacity of assimilating hydrophilic and lipophilic substances which happens e.g. in the pharmacy by simply stirring in these agents at room temperature. Generally, it can be stated that the creams produced by means of the above described procedure are physically very stable so that a minimum shelf life of 6 to 12 months can easily be guaranteed. This system proves to be the ideal solution for both the individually adapted prescription in the pharmacy as well as the practical application in specialized beauty institutes2). Figure: Preparation of emulsions and DMS  Microbiological stability

Adding moisturizing substances like glycerine, oligosaccharides, sorbitol, propylene glycol, pentylene glycol guarantees microbiological stability and results in the fact that besides the moisturizing properties any microbial activity is stopped completely. Combinations of these substances have proved successful. The advantage is, that they avoid sensitizations which, on the contrary, can be observed with the conventional preservatives used in pharmacies and listed in the European Cosmetic Decree. Experiences of the University of Karlsruhe have proved that propylene glycol is perfectly safe too3).

Membranes and emulsifiers

In view of technical formulations, it is very interesting that the different members of the membrane family mix easily and show a high tolerability4). However, just like in liposomes and nanoparticles, additives containing emulsifiers lead to a destruction of the membrane structures. As DMS creams are used in the first place for the treatment of disordered skin or the prevention of it and emulsifiers, as already explained above, rather are detrimental for the skin barrier, this actually is no restriction.

Dermatological and cosmetic applications

Typical DMS dermatological and cosmetic applications either without additives or by adding the appropriate active agents are: - dry and sensitive skin

- neurodermatitis and skin barrier disorders

- bad skin and acne

- (occupational) dermatoses

- elderly skin

In the meantime, several manufacturers have published a multitude of preparations which have been used as a base for a series of modular systems2).

An important advantage of DMS is the smooth transition from the dermatological treatment with pharmaceutical substances to a cosmetic prevention and skin care or vice versa with both using the same cream base.

References 1) H. Lautenschläger, Pharm. Ztg. 144 (13), 1038-1040 (1999)

2) H. Lautenschläger, Kosmetik International 1998 (1), 104-106

3) M. Gloor, K. Thoma und J. Fluhr, Dermatologische Externatherapie, Springer-Verlag, Berlin 2000, S. 146-147

4) H. Lautenschläger, Handbook of Cosmetic Science and Technology, p. 201-209, Marcel Dekker, New York 2001 Dr. Hans Lautenschläger |